$40.00 – $110.00

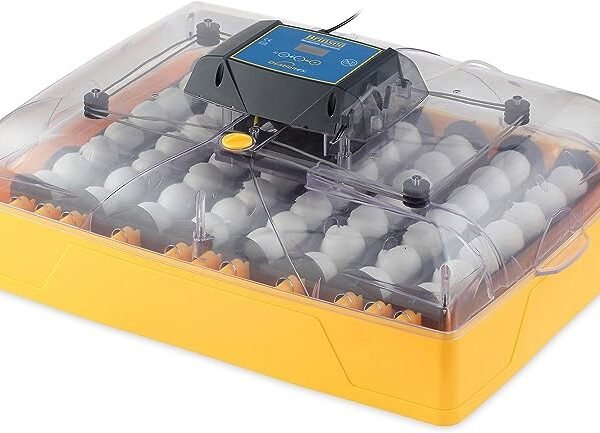

48 Eggs Automatic Egg Incubator Fully Hatchery Machine Mini 48 Chicken Sale Auto Turn For Duck Pigeon Parrot Poultry Supplies – Feeding & Watering Supplies.

Egg Incubator 48 Eggs Fully Automatic Digital Incubators for Hatching Eggs Poultry Hatcher Machine with Temperature Humidity Control and Auto Turning for Hatching Chicken Duck Goose Quail Birds

An incubator is a device simulating avian incubation by keeping eggs warm at a particular temperature range and in the correct humidity with a turning mechanism to hatch them.

The common names of incubators in other terms include breeding / hatching machines, hatchers, setters, and egg breeding / equipment.

Egg Incubator Purposes

The incubator is an apparatus that is used to regulate environmental conditions such as temperature, humidity, and turning for successful hatching of the fertile eggs placed in an enclosure. It is often used for growing bacterial cultures, hatching eggs artificially, or providing suitable conditions for a chemical or biological reaction. The incubator is recorded as being used to hatch bird and reptile eggs. It lets the fetus inside the egg grow without the mother needing to be present to provide warmth. Chicken eggs are recorded to hatch after about 21 days, but other species of birds can take a longer or shorter amount of time. Incubators are also used to raise birds.

An incubator should be able to set the perfect environment and condition for an egg to incubate because it regulates factors such as temperature, humidity, and turning the eggs when necessary, so the egg is incubated properly because it plays the role of the hen in its natural state. The incubator also allows the egg to incubate while eliminating external threats that could possibly harm the eggs.

The modern hatchery manager’s goal is to produce large numbers of uniform, robust, day-old chicks. Robustness is a health criterion, originating in the embryonic life stage of the chicken – and correlating directly with the performance and resistance of individual chicks under differing farm conditions. Incubating different species of birds at the same time is possible within the same incubator.

Incubation methods

In industrial incubation, there are two common methods of incubation: single-stage and multi-stage. In single-stage incubation, the incubator contains only eggs of the same embryonic age. The advantage of single-stage incubation is that climate conditions can be adjusted according to the needs of all the growing embryo. In multi-stage incubation the setter contains eggs of different embryonic ages, usually 3 to 6 age groups. Consequently, climate conditions cannot exactly be adjusted according to the needs of all the growing embryos and a compromise has to be sought to best suit the age groups presented in the setter. In a multi-stage incubation procedure, the heat produced by the older embryos is used to heat the warmth-demanding younger embryos in the same machine. Due to different physical demand in Multi-Stage and Single-stage different equipment is needed to be successful. Many industrial producers use traditional Single-Stage machines, but real single-stage is available.

Egg Incubator Styles

Modern incubators are electrically heated and controlled by a thermostat, while some are powered by solar energy due to epileptic and erratic electricity supplies. They can be used in a farmhouse, such as a large chicken-raising facilities, or they can be found in a common classroom for students to observe the egg inside and when it hatches. Some industrial incubators are large enough to hold up to 124,416 eggs, and some other styles can only hold a few eggs.

The styles of incubators include:

- Setter incubator

- Hatcher incubator

- Combination incubator

| Model | 48 Hatchery Machine Mini 48 parrots Automatic Egg Incubators, 56 Eggs Digital Egg Incubator-WPPET Automatic Incubators, 7 Eggs Currens Automatic Mini Egg Incubator |

|---|

Be the first to review “Egg Incubator Hatchery Machine w/ Temperature Humidity Control” Cancel reply

Related products

Incubators and Brooders

Incubators and Brooders

Incubators and Brooders

Brinsea Maxi 24 Advance Automatic 24 Egg Incubator, Yellow/Blue

Incubators and Brooders

Brinsea Products USAG46C Ovation 56 Advance Automatic Egg Incubator with Humidity Display, One Size

Incubators and Brooders

Brinsea Ovation 28 Advance Automatic Egg Incubator with Humidity Display, One Size

Incubators and Brooders

Reviews

There are no reviews yet.